DESIGNER Companion

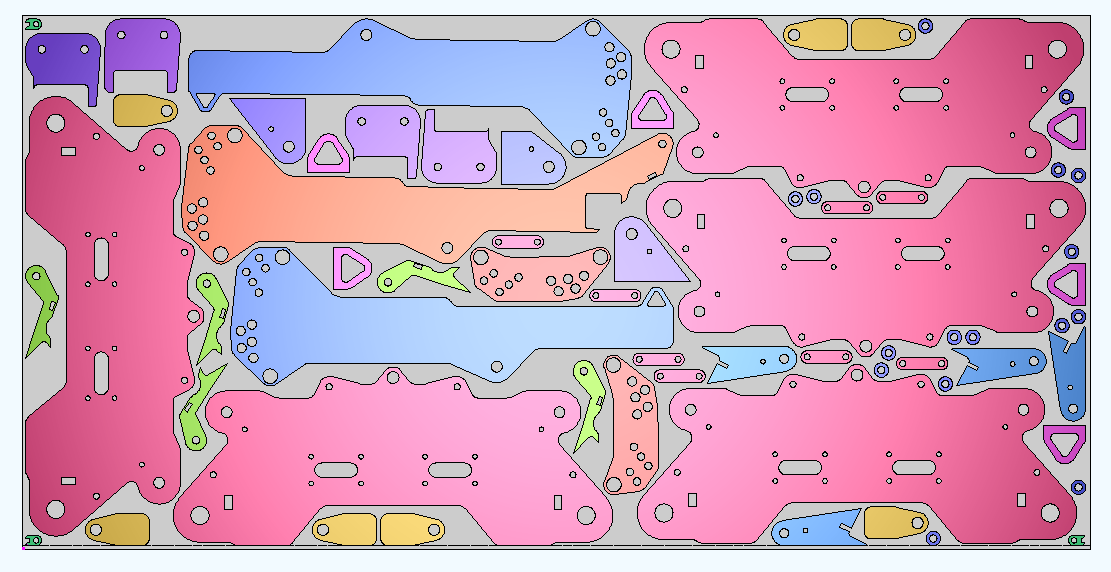

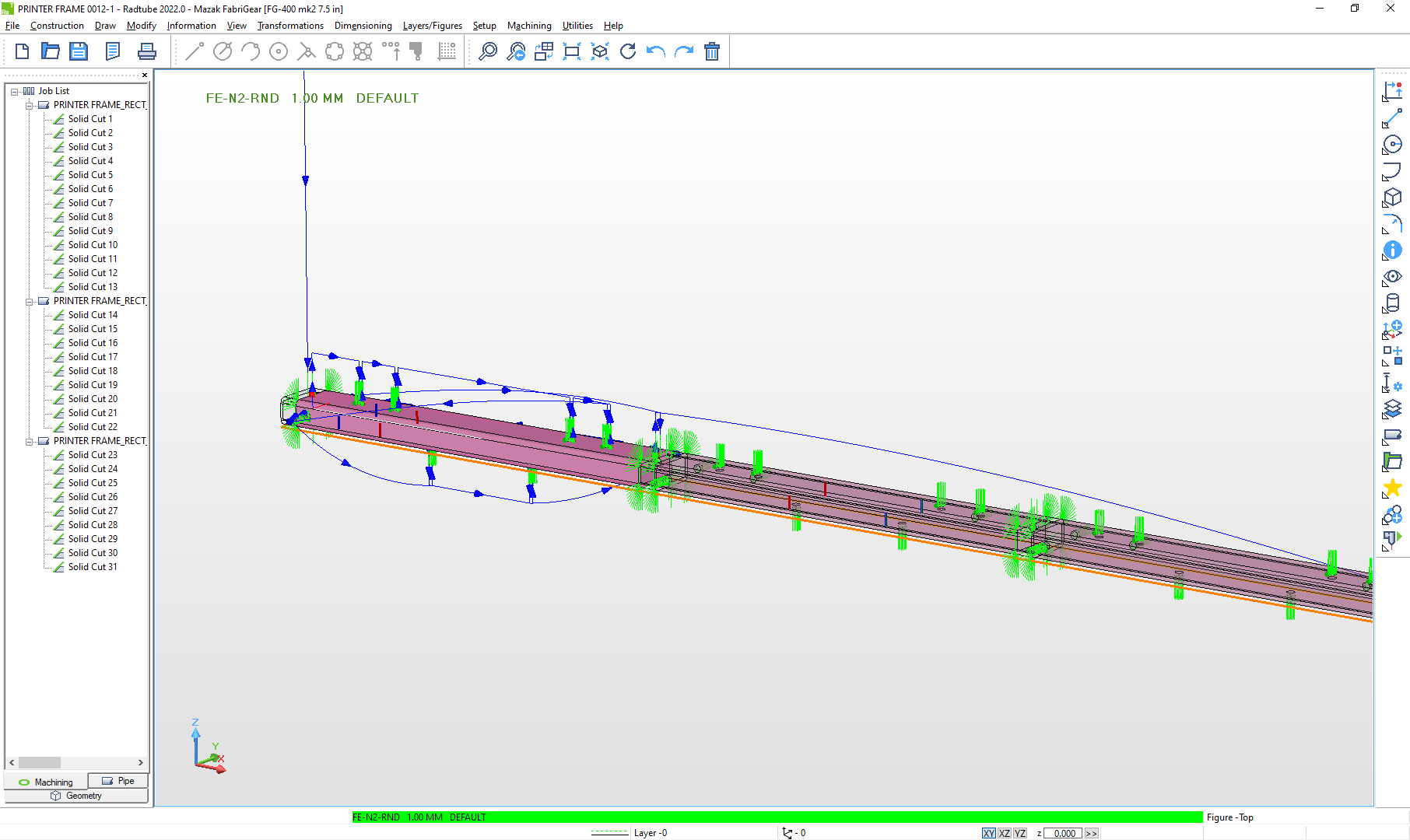

- DESIGNER Companion will be made available to all RADAN customers, as part of their SMA contract:

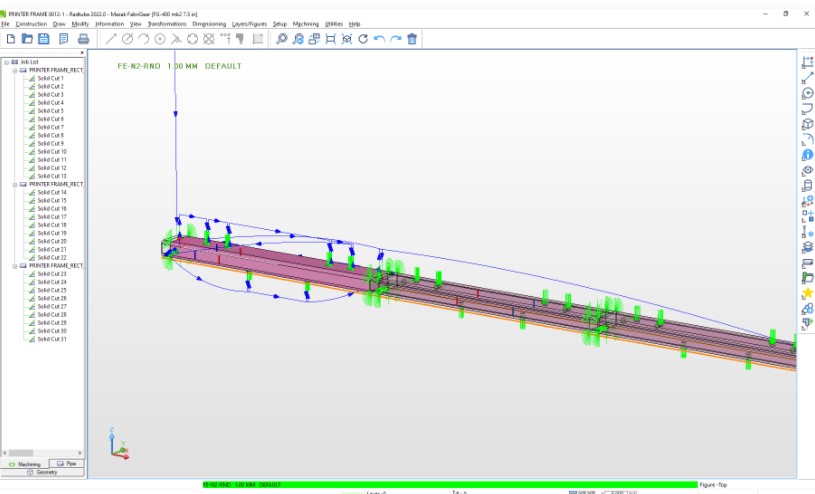

Existing customers will be able to read in 3D files and turn them to sheet metal. The RADAN suite will start from 3D CAD for CAM!

- Radraft DESIGNER Companion:

Gives the ability to deal with 3D files. Unfolding with bending dies related setback included, and possibility to easily create 2D drawings for the production. Direct link with all the RADAN Classic product smoothen the workflow.

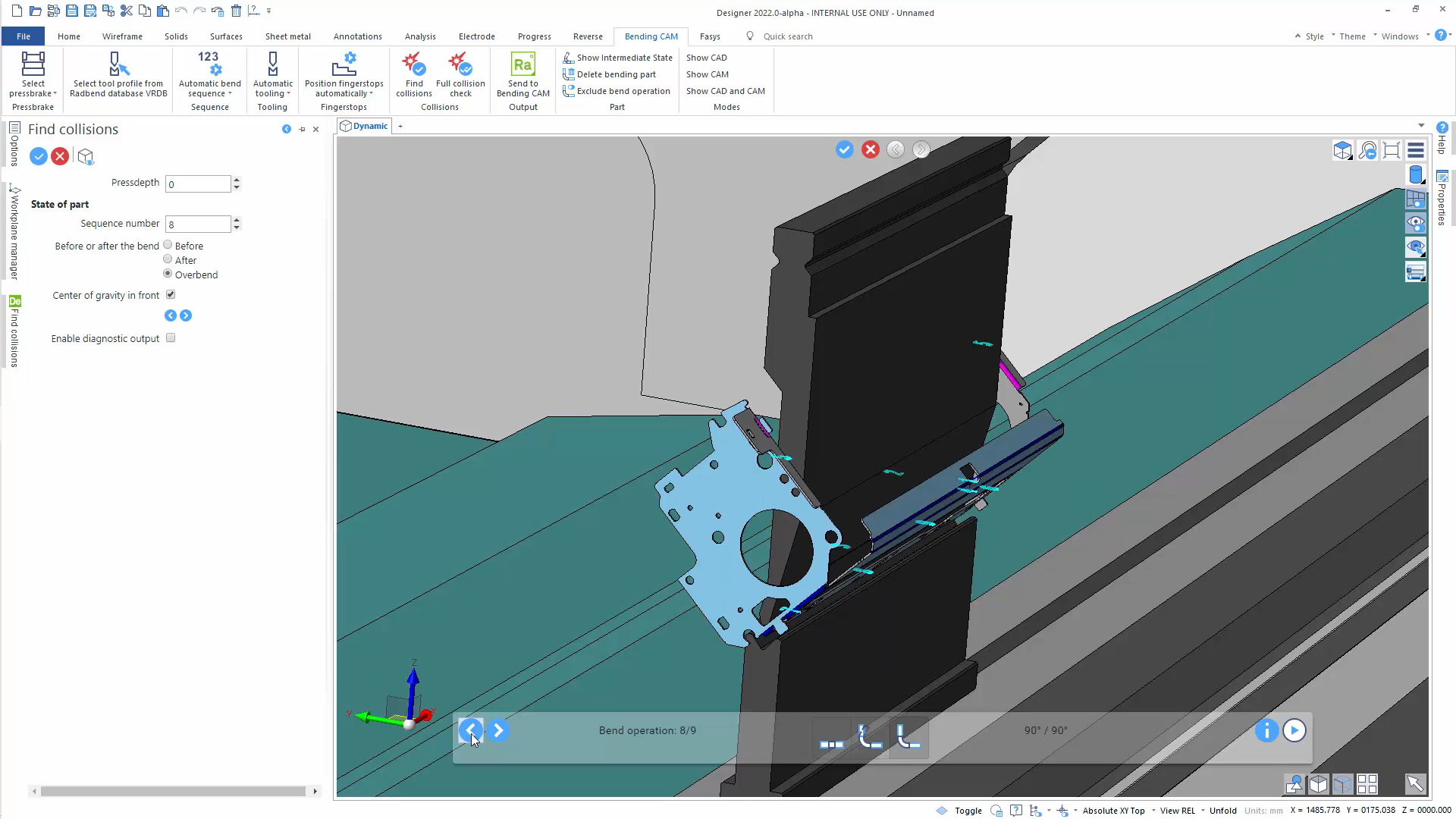

- DESIGNER Companion plus Sheet Metal module:

Direct modelling capabilities offers the possibility to easily modify a ‘look like’ sheet metal part to a real sheet metal part. Part creation is also possible within the same environment.

- DESIGNER stores material data on the SFx platform:

RADAN is connected!.

All data will be stored in the cloud, easy to access anytime from anywhere. Material list and characteristics are stored on SFx, making them sharable and unique.

- Automation on adding bend function:

When adding a bend to a part, DESIGNER Sheet Metal will automatically apply the associated bend relief. A productive way to faster create parts.

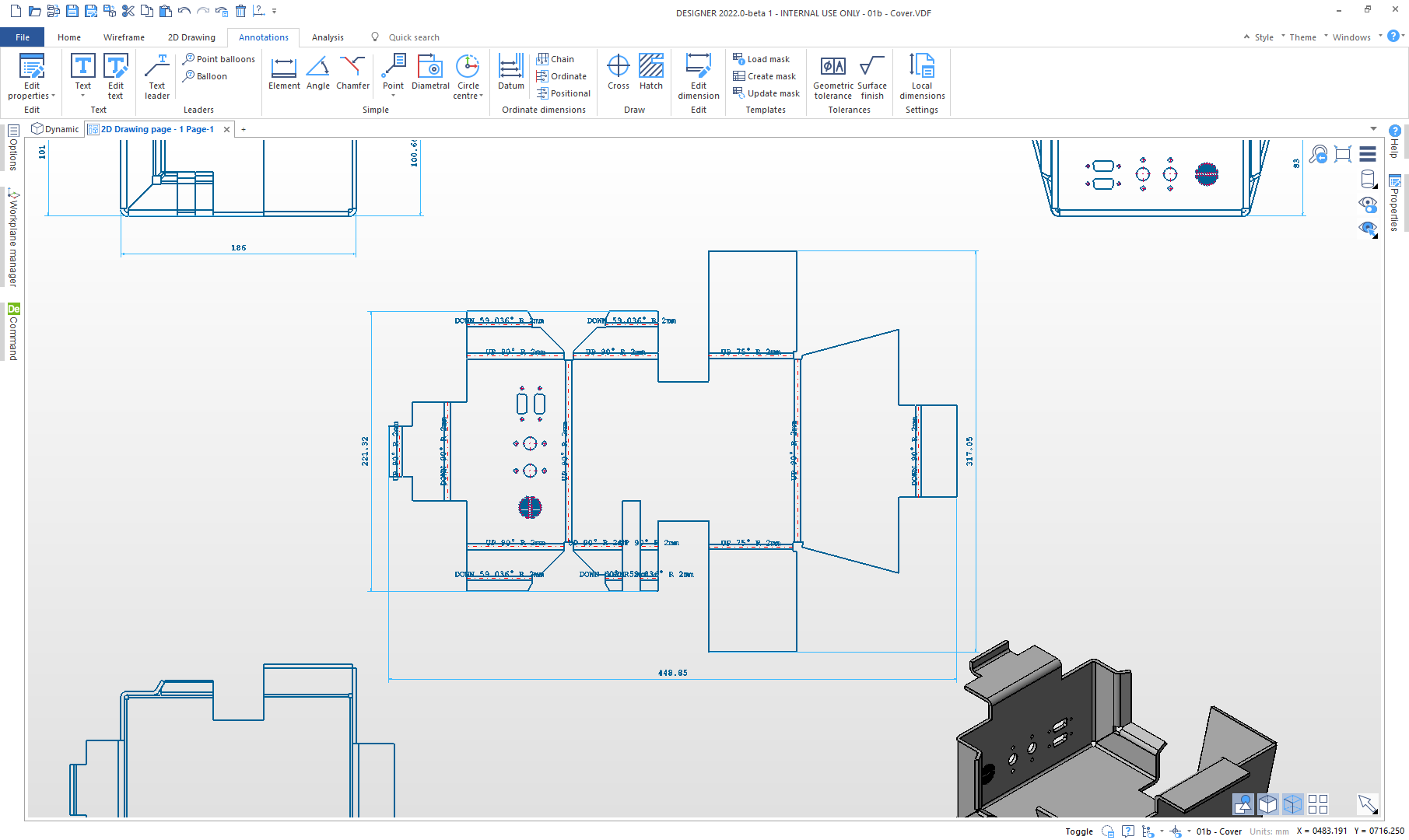

- Add bend lines on the drawing:

Produce documents to share with the bending operator. You can display the bend center line and accurately dimension it.

Help to avoid mistakes and rejected parts in the bending operation. Improve productivity and save material.

|

- Add bend zones on the drawing:

Help the operator to better understand the possible effect of the bending process on the part. Help with global accuracy warning on unexpected shape deformation. Improve part quality.

- Add bend details on the drawing:

Help on passing the relevant information to the bending operator using the drawing. Enhance communication and allow feedback to capture experience from the shopfloor.

|