Radan Products

THE TOTAL CAD/CAM SOFTWARE SOLUTION FOR THE SHEET METAL INDUSTRY

Our strength is in providing world class innovative solutions which will give you the software applications that are essential to design, manufacture and control production of sheet metal Production.

|

RADAN 2D: [Radraft]

HIGHLY EFFICIENT CAD SPECIALISED FOR SHEET METAL | RADAN 2D provides users with a complete solution for 2D drawings which incorporates sheet metal industry expertise. Its many features and easy-to-use graphical interface make RADAN 2D a reliable and economical solution. One of the main requirements of a CAM system used in a production environment is the ability to support inaccurate 3rd party data. RADAN 2D offers a quick and simple method to repair or simplify geometry imported from other systems. |

|

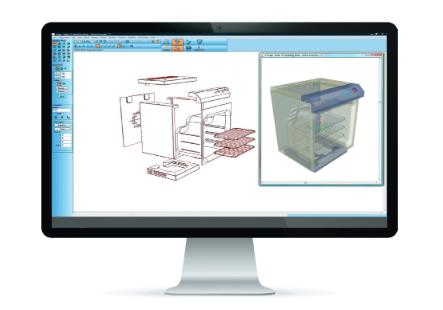

RADAN 3D

3D MODELLING, PART UNFOLDING, AND SHEET METAL FEATURES | RADAN 3D is a fully integrated software application which provides expert functionality in the field of sheet metal 3D development. Simple to use, and fast, RADAN 3D provides unmatched productivity for designing your parts and sheet metal assemblies. Unfolding, notching, managing corners and bend allowance are all standard features when creating geometry using RADAN 3D. This module of the software suite gives the user very easy access to the world of 3D modelling which is essential to companies working in sheet metal. |

|

|

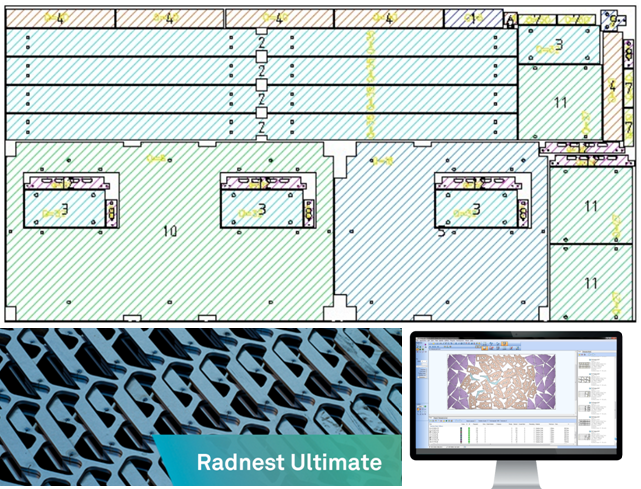

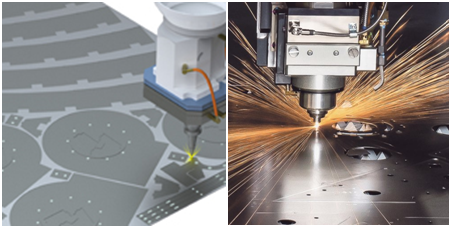

RADAN NESTING: [RADNEST]

AUTOMATIC NESTING ADAPTED TO PUNCHING AND CUTTING MACHINES | It is easy to manage the workflow of your Production and the intelligent features of the integrated project mode in Radnest will manages your production taking into account your raw materials inventory and disposable drops as well as your customers’ deadlines and priorities. Radnest is the nesting solution that enriches both Radpunch and Radprofile. Radnest significantly optimises the use of the sheet and generates substantial savings on raw materials. Radnest analyses all the available sheet sizes allowing the optimum use of material for the production. The differences in parameters between parts are integrated into the technological base by material / thickness / machine to ensure a reliable and optimum production. With the latest V.2023.2 Radnest Ultimate software, you can expect to produce more components from less material in less time. The Radnest Ultimate incorporates fully generalized nesting that analyses the true shape of components, significantly increasing sheet utilization and delivering substantial material cost savings. The software looks at the entire nest run and reduces the number of overall sheets instead of focusing on how full each individual sheet is, providing a significant performance upgrade. |

|

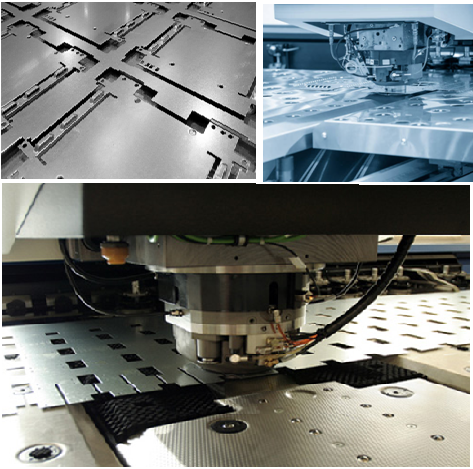

RADAN PUNCH: [RADPUNCH]

PROGRAMMING FOR CNC PUNCHING MACHINES | Radpunch is a market leading solution for the programming punching machines. With over 40+ years of punching experience, RADAN successfully drives thousands of punching machine tools worldwide. This history easily allows us to integrate different generations of punching machines taking into account modern facilities such as FMS cells with component loader and unloaders. The technological basis of integrated punching inside Radpunch means you will be able to automate the programming phases, regardless of the tools used [standard, special, forming, wheels etc.]Radpunch will assist your operators to optimise your manufacturing capacity to within those limits for all of your machines. |

|

|

RADAN PROFILE: [RADPROFILE]

PROGRAMMING FOR LASER CUTTING, PLASMA OR WATERJET MACHINES | Radprofile is a highly automated software solution for laser cutting, plasma, waterjet, and flame cutting machines. Radprofile seamlessly integrates the whole programming process of geometry creation, nesting, cutter patch calculation, sequencing, code generation, and finally DNC connectivity to the machine controller. All the technological functions of your machines are integrated into Radprofile: marking, vaporising, plastics, pulsed, small and large contours, slowdowns, rapid cuts... are all perfectly managed Radprofile modes. The cutting functions of text or scanned drawings are quickly accessible in the software. An exclusive feature positions the lead-ins, ensuring safe movement and increasing productivity. The software also automatically manages the order of cutting depending on the heat build-up in the material. |

|

RADTUBE & RADM-AX:

PROGRAMMING OF TUBE CUTTING MACHINES | MULTI-AXIS LASER CUTTING Radtube interfaces with any CAD solution on the market. It comes with standard interfaces such as IGES and DXF, but also comes with native formats like DWG, Inventor, VISI, SolidWorks, Solid Edge, and IronCAD. Radtube is compatible with most machines on the market such as Adige, NTC, Trumpf, Mazak and Amada... If a machine is not on the list, Radtube fits the definition of the machinery to achieve the processors on demand. Radm-ax is the multi-axis extension of Radtube and allows the programming of laser cutting machines, water jet, and other technologies. These two programs share the same basic graphics so naturally you will find them similar in Radm-ax’s capacity of the import and treatment of 2D and 3D files. Radm-ax also has a powerful post-processor generator to finalise the CNC code and achieve a precise definition of the machine simulation.M Collision detection of the cutting/machine head uses very fast algorithms, making it simple and safe for programming. |

|

|

Radan Import:[Radimport]

With Radimport you can select multiple DXF or DWG files and add or edit the additional information. Importing files can also be done with a configurable parts list in a CSV format, as you might get from an MRP system

|

|

RADQUOTE - INTELLIGENT QUOTING

Radquote is a sheet metal quotation program that will enable you to quickly and easily create quotes for sheet metal parts and purchased parts. It gives you a full breakdown of the costs and allows you to alter each cost area to give you the flexibility you need when negotiating. Flexible reporting allows you to send professional quotations and make internal reports for analysis. Customer management and reminders help you track active quotes and record success rates.

|

|

WORKPLAN AND RADAN

WORKPLAN is an intelligent Project Management solution combining Sales & Production Management and MES functionality within a single database. As the backbone of your manufacturing company, WORKPLAN becomes the main tool centralizing your company's data in order to improve your production management. For example, machine events, monitoring, CMMS, CAM supervision, production workflow, and part traceability on the shop floor. STOCK AND NEST WORKPLAN offers a simple and efficient stock management solution for sheet metal nests including stock reception/withdrawal, inventory, scrap management and part traceability. Interfaced with the CAM programming software, data reporting in WORKPLAN and deduction of sheets consumed is available with just a few clicks. |

|

|

PROGRAMMING OF CNC PRESS BRAKES

Radbend can greatly increase the productivity of press brakes. Compatible with all numerically controlled generations of belending machines, the offline preparation can signficantly increase the production time of the press brakes.

|

|

Software updates

Receive annual software updates during the subscription period giving you the latest functionality and ensuring maximum productivity and efficiency. There is one major software release per year plus service packs.

OVER 5,000 DIFFERENT MACHINES ARE SUPPORTED The RADAN headquarters are located in Bath, England, and the company has offices in Germany, Italy, France, Japan, USA, Netherlands, China, Korea, Spain and INDIA supplying products to more than 45 countries through its wholly owned subsidiaries and global reseller network. |